Developed tools

Info

Enjoy summer, we'll be back in autumn.

Design of Hybrid Electric Propulsion of Aircraft is starting to form its shape

On 19th and 20th November 2018 MAHEPA Consortium Meeting was held at Merklingen, Germany to discuss the progress made on the development of modular architectural concepts for hybrid electric aircrafts and to plan further activities in powertrain system design, component specifications, software specifications, power management, etc. So far PMCD (power management, control and delivery) module with software and functional specifications has been defined together with intra-component high level communication interface, which will allow a single or multiple PMCDs to achieve oversight and control over an arbitrary serial hybrid powertrain.

Also scalable hybrid electric fuel cell powertrain with intermediate steps has been designed to optimize power management and achieve enhanced levels of performance. Unlike conventional fuel-powered aircraft, where the relation between engine thrust and fuel consumption is a one-dimensional functional, hybrid-electric aircraft will operate in a bi-dimensional space, where different power management methods will be explored. The most perspective power management methods will then be developed as a high-level control function of the PMCD module using the API layer and tested in flight.

During the meeting partners of the project MAHEPA were also taken to the laboratories of University of Ulm, where they could see, how the pilot components of hydrogen aircraft are being tested. The laboratories of University of Ulm have three main setups, which could be seen during the visit. The first one is the Emrax test bench, where Emrax electric motor is connected to a load machine to test it under different load conditions. The second setup is the vacuum chamber, where the HY4 power system will be tested under low pressure to simulate the ambient conditions of the airplane during flight. The last setup was the Rotax combustion engine test room, which will also be connected to a load machine and tested under different load conditions. Not only partners’ excellent knowledge and experience but also outstanding research and laboratory facilities has shown to be the key success factor of MAHEPA project.

-

SMACKER final conference recording

Recording and materials from SMACKER final conference are published.

-

Join SMACKER Final Conference

You are cordially invited to join the final conference of SMACKER project, taking place in Vienna (AT) on 23. May 2022.

-

Join SMACKER webinar on Demand Responsive Transport

You are cordially to online scientific event on Demand Responsive Transport organized within SMACKER project taking place on 10th of November 2020.

-

eGUTS final conference

eGUTS final conference took place in Zadar (Croatia) on 17. September 2019.

-

E-Carriage 4CBST Study tour in Braunwald, Switzerland

In the scope of the E-Carriage 4CBST project, project partners from Slovenia and Austria organized a study tour to Switzerland on May 16th and 17th, 2019, more specifically to Braunwald, which is renowned for its eco-friendly tourism, which offers, among other things, a holiday experience without the presence of car use.

-

Prva študijska tura: Obisk ranča Zalai Lovas Kft. na Madžarskem

There are no translations available.

V okviru čezmejnega projekta Kočijaške poti za e-kočije: spodbujanje naravi prijaznega čezmejnega trajnostnega turizma s pomočjo inovativnih turističnih produktov - E-Carriage 4CBST smo se projektni partnerji iz Slovenije in Avstrije podali na prvo od treh načrtovanih študijskih tur.

-

R&D solutions of the MAHEPA project: The future lies in a modular approach

-

eGUTS project presentation at a conference The Danube Region Transport Days

The Danube Region Transport Days were held in Ljubljana on 4th and 5th of December 2018, where project eGUTS was presented. -

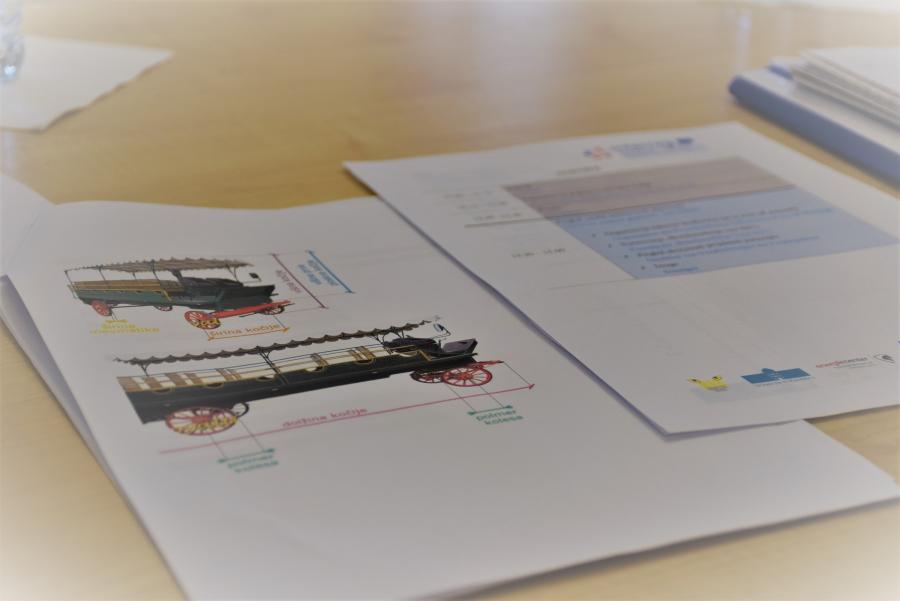

Predstavitveni dogodek projekta E-Carriage 4CBST in delavnica s srečanjem projektne vodilne skupine

There are no translations available.

V torek, 04. 12. 2018, je v EC Energie Center Lipizzanerheimat v Bärnbachu (AT) potekal predstavitveni dogodek projekta Kočijaške poti za e-kočije: spodbujanje naravi prijaznega čezmejnega trajnostnega turizma s pomočjo inovativnih turističnih produktov, krajše E-Carriage 4CBST.

-

eGUTS at the 5th conference on Transport and Research in the Danube Region

On 13th and 14th of November the 5th conference on Transport and Research in the Danube Region took place in Ljubljana, Slovenia. -

Project SULPiTER presented at 5th conference on Transport and Research in the Danube Region

On 13. and 14. of November 2018 5th conference on Transport and Research in the Danube Region was held at Hotel City in Ljubljana, where project SULPITER was presented. -

Training Course: How to write a proposal in HORIZON 2020

Within the RADIAN project a training course: How to write a proposal in HORIZON 2020 was held on 23rd of November 2018 at Faculty of Civil Engineering, Transportation Engineering and Architecture. -

Representatives from Slovenian automotive cluster visit Transport Economics Centre

-

Design of Hybrid Electric Propulsion of Aircraft is starting to form its shape

On 19th and 20th November 2018 MAHEPA Consortium Meeting was held at Merklingen, Germany to discuss the progress made on the development of modular architectural concepts for hybrid electric aircrafts and to plan further activities in powertrain system design, component specifications, software specifications, power management, etc.

-

1. delavnica za pripravo hibridne E-kočije projekta E-Carriage 4CBST

There are no translations available.

V četrtek, 8.11.2018 se je v okviru projekta E-Carriage 4CBST, v prostorih Raziskovalno-izobraževalnega središča Dvorec Rakičan, izvedla prva delavnica za pripravo hibridne e-kočije.

-

Kick-off sestanek za projekt E-carriage 4CBST v RIS Rakičan

There are no translations available.

-

eGUTS Regional Strategy Platform's first meeting

Within EU financed project eGUTS the first meeting of eGUTS Regional Strategy Platform took place on 12th of Decembre 2017 at Municipality of Velenje.

-

Webinar video on Freight Quality Partnership with Prof Michael Browne

SULPiTER Webinar video on Freight Quality Partnership with Prof Michael Browne now available

-

SULPiTER Webinar on Freight Quality Partnership with Prof Michael Browne

Webinar on Freight Quality Partnership (FQP), 28. November 2017 from 14:00 to 15:30 (CET)

-

MAHEPA is one step closer to flying innovative hybrid electric aircraft

-

Second meeting of eGUTS project took place in Maribor

The second meeting of eGUTS project took place in Maribor between 2nd and 4th of October 2017. The meeting was hosted by University of Maribor, Faculty of Civil Engineering, Transportation Engineering and Architecture.

-

SULPiTER Enlarged Transfer Programme

The SULPiTER Enlarged Transfer Programme (ETP) aims to train the participants to enhance their understanding and skills in policy making for urban energy efficient freight in a mutual learning process.

-

Webinar "Trends influencing regional logistics planning"

Transnational Open Trainings/Webinars “Trends influencing regional logistics planning”

15. and 22. May 2017 -

World’s most powerful hybrid electric powertrain unveiled at AERO 2016

Prototype of the world’s most powerful hybrid electric powertrain for general aviatio unveiled at AERO 2016 -

Most powerful hybrid electric powertrain powers up

A major step towards electric powered air travel was achieved on 9th February 2016 with the power-up of the world's most powerful hybrid electric powertrain for aviation in a project led by Pipistrel. Hybrid-electric powertrains are a new breed of aviation propulsion, which extend the range of all-electric aircraft while being environmentally friendly and quiet. The 200 kW propulsor developed during the project HYPSTAIR delivers the power equivalent to a typical general aviation piston engine and can run in three modalities: electric-only mode using batteries, generator-only mode or hybrid mode combining both power sources. -

Project HYPSTAIR at E2-Flegen Simposium

HYPSTAIR project has, in cooperation with the DLR and University of Stuttgart, organised the Symposium E2 Flying. The Symposium addressed the challenges related to implementation of aircraft with electric drive.

-

Project HYPSTAIR at Aerodays 2015

Aerodays 2015 took place from 20th to 23th October 2015 in London. Aerodays is the European flagship three-day event in aviation research and innovation, which takes place once every 4 years, during each EU Research Framework Programme. Designed to present strategic perspectives for aviation, including research and innovation, the event goal is to share achievements of collaborative research and innovation in aeronautics and air transport within Europe and world-wide international co-operation.

-

International Conference on Sustainable Energy and Environmental Protection (SEEP 2014)

From 23th till 25th November, the International Conference on Sustainable Energy and Environmental Protection took place in Dubai. The conference, organized by The British University in Dubai and University of the West of Scotland, is focused on sustainable energy and environmental protection.

-

The 3rd Annual Conference on Transport, Trade and Service Studies (ATTSS)

On 17th and 18th November, the 3rd Annual Conference on Transport, Trade and Service Studies took place at City University of Hong Kong. Dr. Stane Božičnik as a chairman of session on Transport and Trade Logistic, presented NAPA Ports Developing Challenges and Opportunities for Far Eastern Transport Market. Participation at the conference is the result of good research and academic collaboration between the Centre for Transport, Trade and Financial Studies (CTTFS) from City University of Hong Kong and Transport Economics Centre (TEC) from University of Maribor.

-

Cooperation challenges in research between University of Maribor and City University of Hong Kong

Following the invited lecture of dr. Stane Božičnik at City University of Hong Kong and Centre for Transport, Trade and Financial Studies (CTTFS), Transport Economics Centre (TEC) now hosted professor and director of CTTFS, John Jianhua Liu, in Maribor on a three day visit.

The aim of the visit is to consider possibilities for future cooperation among University of Maribor (TEC) and City University of Hing Kong (CTTFS).